The cooling system of screw air compressors serves as the “temperature control core” for stable equipment operation. Its function is to promptly dissipate heat generated during compression, ensuring oil temperature and discharge temperature remain within safe limits (typically oil temperature ≤85°C, discharge temperature ≤100°C). Cooling system failure can lead to increased energy consumption and degraded lubrication at best, while at worst causing high-temperature shutdowns and shortening the host unit's lifespan. Therefore, scientific maintenance is essential for users:

I. Necessity of Cooling System Maintenance (Why Maintain?)

The core function of the cooling system is “heat dissipation,” whose performance directly impacts the air compressor's operational efficiency, lifespan, and safety. The necessity of maintenance manifests in the following five dimensions:

1. Maintaining Heat Dissipation Efficiency to Prevent Equipment Overheating

Dust accumulation on air-cooled radiators reduces heat exchange area, decreasing cooling capacity by over 50%.

Annual Maintenance

Replace Coolant (Closed System): If antifreeze is used, check the freezing point (should be at least 5°C below the local minimum temperature). If the freezing point has risen or the fluid is cloudy, completely drain and replace with new antifreeze.

Water Pump Bearing Maintenance: Disassemble the pump housing to inspect bearing wear. Replace grease (lithium-based grease, filling 1/2 to 2/3 of the bearing cavity).

Comprehensive Pressure Test: Perform a 0.6MPa pressure test on the entire water cooling system. Maintain pressure for 30 minutes. A pressure drop ≤0.05MPa is acceptable. Otherwise, locate and repair leaks.

A 1mm scale buildup in water-cooled system pipes lowers heat transfer efficiency by 20-30% (scale's thermal conductivity is only 1/50th of metal).

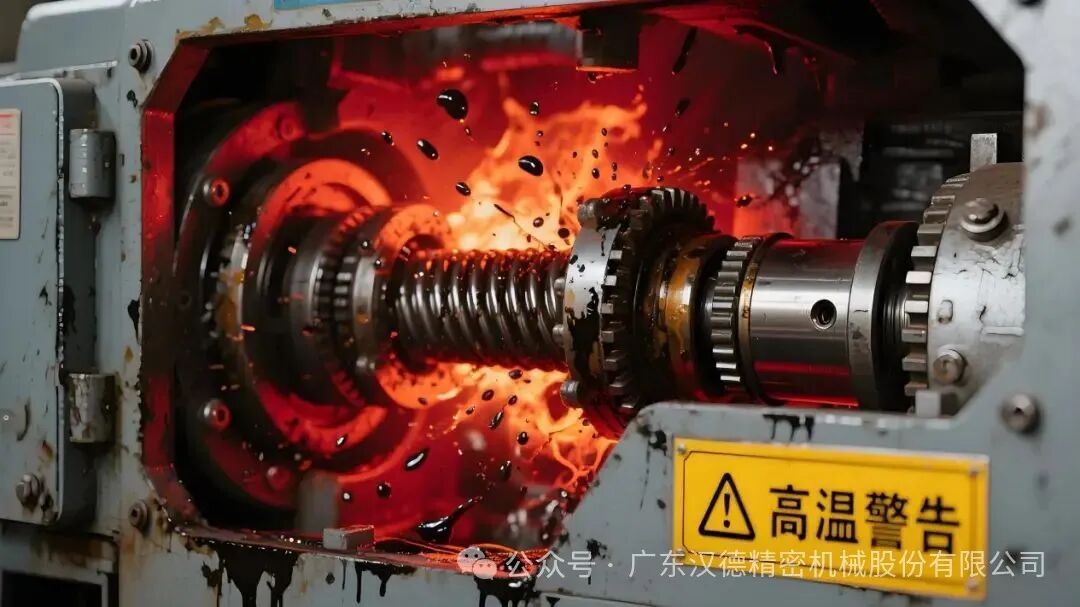

Insufficient cooling causes oil temperature and exhaust temperature to surge. When exceeding safety thresholds (e.g., exhaust temperature >110°C), the equipment triggers protective shutdown. Prolonged overheating causes lubricant failure (oil film breakdown) in components like rotors and bearings due to high temperatures, leading to wear, cylinder seizure, or even rotor lockup.

2. Prevent corrosion and leaks to safeguard system integrity

In water-cooled systems, poor water quality (e.g., high oxygen content or abnormal pH levels) can cause corrosion (electrochemical or chemical) in cooler pipes and radiator walls, forming holes or cracks that lead to leaks.

In air-cooled systems, oil residue and moisture-laden dust on radiator surfaces can form viscous deposits, accelerating oxidation and rusting of metal fins, which further reduces heat dissipation area.

3. Extend Core Component Lifespan

Cooling system failure indirectly accelerates wear on critical components:

High temperatures cause lubricant viscosity to decrease, weakening lubrication and accelerating friction wear on bearings, gears, and other parts;

Excessively high exhaust temperatures accelerate the aging of oil-gas separator filter elements (high temperatures cause filter fibers to become brittle), reducing filtration efficiency. This leads to excessive oil content in compressed air and increases the replacement frequency of oil-gas separators.

4. Ensuring Compressed Air Quality

The final temperature of compressed air is directly related to the cooling system: if cooling is insufficient and discharge temperatures are excessively high (e.g., exceeding 100°C), the air entering the dryer will far exceed its design processing range. This renders the drying process ineffective, causing moisture content in the compressed air to surge.

Moist compressed air can cause corrosion and blockages in end-use equipment (e.g., pneumatic valves, precision instruments) and even impact product quality (e.g., in electronics and food industries).

5. Reduce Energy Consumption and Operating Costs

Declining cooling efficiency triggers a “chain reaction of increased energy consumption” in air compressors:

High temperatures reduce air density (decreased mass per volume), forcing compressors to consume more power to achieve rated airflow (airflow decreases by approximately 2% for every 10°C increase);

Frequent shutdowns due to overheating cause restart surges of 3-5 times the rated current, significantly increasing electricity consumption;

Failure repair costs far exceed regular maintenance expenses (e.g., replacing a cooler costs 5-10 times more than annual maintenance).

II. Maintenance Methods for Cooling Systems (Air-Cooled and Water-Cooled Types)

Screw air compressor cooling systems are primarily categorized into air-cooled (using fans for forced air cooling) and water-cooled (using circulating cooling water for heat dissipation). Their structures differ, and maintenance methods also vary accordingly.

(I) Air-Cooled System Maintenance

Core Components: Air-cooled radiator (finned heat exchanger), cooling fan (axial or centrifugal), air ducts, air filter.

Maintenance Objectives: Remove obstructions from radiator surfaces, ensure proper fan operation, and maintain unobstructed airflow.

Daily Inspection (Daily)

Observe whether the instrument display readings for “exhaust temperature” and “oil temperature” are within normal ranges (exhaust ≤ 100°C, oil temperature ≤ 85°C);

Listen for abnormal fan operation sounds (unusually loud noises, stuttering), and inspect fan blades for deformation or cracks;

Check if the radiator surface is covered with noticeable dust, lint, leaves, etc. (especially near the intake side).

Regular Cleaning (Adjust based on environment; typically once per week, or every 2-3 days in dusty/lint-heavy environments)

Radiator Surface Cleaning:

Use compressed air at 0.4-0.6MPa to blow from the “inner side toward the outer side” of the radiator (avoid blowing from the outside to prevent dust from being forced deeper into the fins);

If oil contamination is present (e.g., from nearby oil mist) and cleaning on-site is not feasible, remove the radiator for cleaning. First, spray with a neutral detergent, let sit for 5 minutes, then rinse with a high-pressure water gun (pressure ≤0.8MPa, distance ≥30cm). Finally, blow dry with compressed air, reassemble, and test to ensure no oil leaks.

Caution: Do not scrape fins with hard objects (e.g., wire brushes) to prevent deformation (which may block airflow channels).

Fan and Motor Cleaning:

Blow dust off fan blades. Inspect motor housing cooling vents for blockages (clean with a small brush).

Check fan guard for secure attachment and damage (to prevent foreign objects entering blades).

Monthly Inspection

Inspect fan drive mechanism (if belt-driven): Check belt tension (press center of belt; deflection should be 10-15mm), inspect for cracks or slippage marks; if direct-drive motor, check motor bearings for abnormal noise and replenish grease if necessary.

Check duct sealing: Inspect connections between ducts, radiators, and fans for gaps (repair with sealant) to prevent “short-circuited airflow” (air bypassing the radiator).

Use an infrared thermometer to measure the temperature difference between radiator inlet and outlet (normal ≥15°C; if <10°C, insufficient cooling efficiency indicates priority cleaning or inspection is needed).

Annual Maintenance

Remove the radiator and repair bent fins using a specialized fin comb (for deformed fins);

Check the insulation resistance of the fan motor (using a megohmmeter, ≥2MΩ) to prevent electrical leakage;

Replace aged fan belts (even if no visible damage is present, replacement is recommended after 2 years of use).

(II) Water-Cooled System Maintenance

Core Components: Water cooler (shell-and-tube or plate heat exchanger), circulation pump, water tank (or cooling tower), filter (water filter), water piping, valves, thermostatic valve.

Maintenance Objectives: Control water quality (prevent scaling and corrosion), clear pipe blockages, ensure unobstructed water circulation, maintain heat exchange efficiency.

Daily Inspection (Daily)

Observe whether “inlet water pressure” (normal range 0.2-0.4MPa), “outlet water temperature” (≤45℃), and “oil temperature” (≤85℃) are within normal limits;

Check for leaks at pipe connections (flanges, valves, joints);

Observe the water tank level (for closed systems) or cooling tower water level (for open systems). Top up if low (use softened water or deionized water; never add tap water directly).

Weekly Maintenance

Clean water filter: Close the valves before and after the filter, remove the filter cartridge, and rinse with clean water (if using a paper filter cartridge, replacement is recommended);

Check Water Pump Operation: Listen for abnormal noises, check pump body temperature (≤70°C), inspect seals for leaks;

Inspect Cooling Tower (Open System): Remove floating debris (leaves, plastic, etc.), observe for damaged or scaled fill material (flush or replace if clogged), verify cooling tower fan operation (same method as air-cooled fan inspection).

Monthly Maintenance

Water Quality Testing:

Test pH using test strips (should be maintained between 7-9; acidic conditions promote corrosion, alkaline conditions promote scaling);

Test hardness (calcium and magnesium ion concentration ≤50mg/L; add scale inhibitor if exceeded);

Test turbidity (≤10NTU; replace water or filter if exceeded);

Check Temperature Control Valve (for regulating cooling water flow): Manually test valve core operation for smoothness (power off, disconnect pipes, push valve core—must move freely without sticking). If stuck, disassemble for cleaning or replace;

Inspect Pipe Supports: Check for loosening or corrosion. Tighten immediately or remove rust and repaint.

Quarterly / Semi-Annual Deep Cleaning (based on scaling severity)

Internal descaling for shell-and-tube or plate coolers:

Chemical cleaning: Drain system water, close inlet/outlet valves, inject descaling agent through access port, circulate for 2-4 hours (maintain 40-50°C to accelerate reaction), then flush 3-5 times with clean water until pH neutral;

Physical cleaning: For stubborn scale, flush the tube side with high-pressure water jets (10-20MPa pressure) after removing the cooler end caps, or use specialized pipe cleaners;

Plate-type coolers require disassembly for cleaning: Loosen clamping bolts, remove plates, and scrub surfaces with a soft brush dipped in neutral detergent (avoid scratching sealing surfaces). Inspect gaskets for aging or damage and replace promptly.

Annual Maintenance

Replace Coolant (Closed System): If antifreeze is used, check the freezing point (should be at least 5°C below the local minimum temperature). If the freezing point has risen or the fluid is cloudy, completely drain and replace with new antifreeze.

Water Pump Bearing Maintenance: Disassemble the pump housing to inspect bearing wear. Replace grease (lithium-based grease, filling 1/2 to 2/3 of the bearing cavity).

Comprehensive Pressure Test: Perform a 0.6MPa pressure test on the entire water cooling system. Maintain pressure for 30 minutes. A pressure drop ≤0.05MPa is acceptable. Otherwise, locate and repair leaks.

III. Maintenance Precautions

Before performing maintenance, the machine must be shut down, power disconnected, and all system pressures released (including cooling system and internal air compressor pressures) to prevent burns or media ejection.

When cleaning air-cooled systems in environments with extremely high dust concentrations (e.g., cement plants, woodworking shops), installing a “pre-filter” (such as a louver-type filter) is recommended to reduce radiator clogging.

Water-cooled systems must not use river water or well water (containing silt and microorganisms) directly as cooling media. Water must undergo softening treatment (or use a closed-loop system + antifreeze).

Post-maintenance trial operation is required: Start the air compressor and observe whether the temperature gradually drops to the normal range (e.g., oil temperature rises from room temperature at shutdown to a stable value within 30 minutes, and ≤85°C). Confirm no leaks before resuming normal operation.

Conclusion:

Maintenance of screw air compressor cooling systems represents a critical “small investment, big return” strategy: Regular cleaning, inspection, and upkeep preserve heat dissipation efficiency, prevent equipment overheating, extend service life, ensure air quality, while simultaneously reducing energy consumption and failure risks. In practice, maintenance frequency should be adjusted based on cooling method (air-cooled/water-cooled) and environmental conditions (dust, humidity, water quality, etc.) to ensure the system consistently operates at peak performance.

No.4 Shishang Road, intelligent Equipment industry Park,Yuanzhou Town ,Boluo County,Huizhou City,Guangdong

Global Service Hotline: 400-897-0566

Tel:+86 752-6688208 6688209 6688516

E-mail:sales@gdhdair.com